| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Jiayuan

Model Number : RCGF

Certification : CE SGS

Place of Origin : Jiangsu, China (Mainland)

MOQ : 1 set

Price : US $1,000 - 50,000 / Set

Supply Ability : 5 Set/Sets per Month

Delivery Time : 25 work days

Packaging Details : Wooden case is our usual practice, we can also pack as our customer's requirement

Type : Beverage Filling Machine

Driven Type : Electric Driven

Usage : Beverage Packaging

Filling material : Flowing Liquid

Material : Stainless Steel

Bottle type : Round Bottle

Electric Stainless Steel 3000 - 14000BPH Beverage Filling Line 4 In 1 Hot Filling

Brief Introduction:

This juice machine integrates washing, filling and capping into one unit, it can be used for hot-filling production of different kinds of fruit juice, tea. This orange juice hot filling machine can also be used for the filling of purified and mineral water.

Main feature of our juice filling machine

1). The parts which contact with the liquid are made of SUS304 stainless steel.

2). All the electrical parts and pneumatic components are supplied by world famous supplier, such as PLC and inverter are from MITSUBISHI, pneumatic components is from FESTO (SMC is an option), Motor is from SEW, contactor and breaker are from DELIXI, touch screen is from WEINVIEW, etc. With these top quality components, the water filling machine runs stably

Standard juice filling machine is as following:

1). The raw water will be purified and sterilized after passing through the water treatment system, and will be stored in the purified water storage tank;

2). The juice will be prepared by the juice preparation system, the prepared juice is stored in the insulation tank (for heat preservation) temporarily;

3). Automatic heat resistance PET bottle blow molding machine is connected with the water filling machine by the Air conveyor;

4). Prepared juice will be pumped into the juice filling machine; At the same time, empty bottles pass through the rinsing, filling and capping 3-in-1 monoblock, the bottles will be rinsed, filled and capped.

5). Bottled water goes out from the orange juice hot filling machine and will be transferred to the bottle over-turn sterilizing machine, the cap and the bottle mouth will be sterilized after passing through the sterilizing machine, then the bottles will be transferred to the bottle cooling machine;

6). The bottles are getting dried after passing through the blowing dryer, and the dried bottle will go to the labeling machine and PE film shrink wrapping machine;

7). The packed bottle water will come out from the PE film shrink wrapping machine.

Advantages of our juice filling machine

1). Full filling to avoid the liquid level from sinking after the bottle cooling down, and to decrease the dissolved oxygen to the utmost extent.

2). Reasonable structured storage hopper and material supply system make the material in constant flow speed, constant pressure without frothing. Usually high position tank is adopted.

3). The storage hopper has the characteristic of gas discharge, full sealing and temperature detecting. In moderate and high speed production line, the material distributor replaces the big liquid tank to realize the complete CIP.

4). Sanitary filling head system is of umbrella structure, high filling speed.

5). Perfect filling temperature control system.

6). Reflux tank system has the function of supplying the material automatically.

7). Perfect CIP system.

| Model | RCGFB 16-1-12-6 | RCGFB18-12-18-6 | RCGFB24-18-24-8 | |

| Number of rinsing head | 16 | 18 | 24 | |

| Number of pulp filling head | 12 | 12 | 18 | |

| Number of juice filling head | 16 | 18 | 24 | |

| Number of capping head | 6 | 6 | 8 | |

| Rated production capacity | 4000BPH | 6000BPH | 10000BPH | |

| Installed capacity | 3.8 | 4.3 | 6.5 | |

| Overall size | 3050×2000×2300 | 3170×2070×2300 | 4070×2350×2300 | |

| Model | RCGFB 32-24-32-10 | RCGFB 40-32-40-12 | RCGFB 50-40-50-15 | |

| Number of rinsing head | 32 | 40 | 50 | |

| Number of pulp filling head | 24 | 32 | 40 | |

| Number of juice filling head | 32 | 40 | 50 | |

| Number of capping head | 10 | 12 | 15 | |

| Rated production capacity | 12000BPH | 15000BPH | 20000BPH | |

| Installed capacity | 8.7 | 9.5 | 12 | |

| Overall size | 5100×2600×2300 | 6250×3050×2300 | 7500×3900×2300 | |

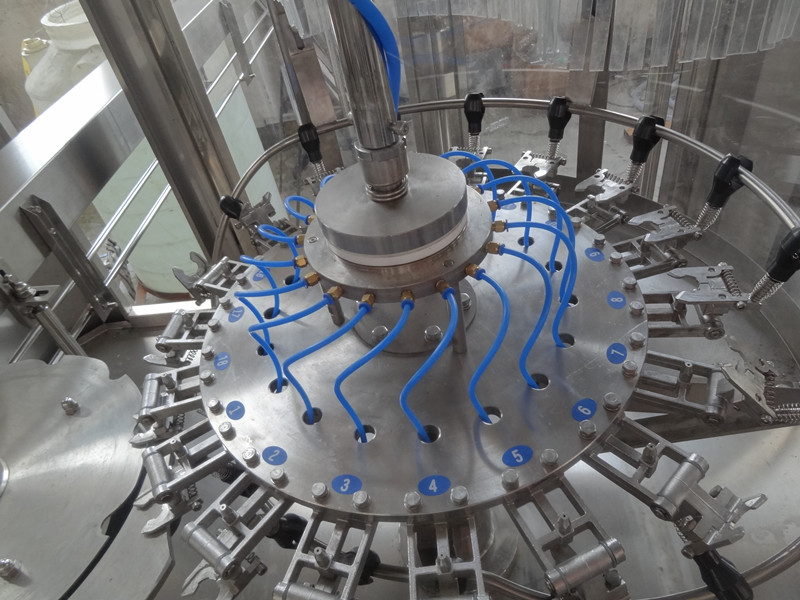

Our Machine Picture

Pls contact me and let's talk more details, thanks in advance!

Zhangjiagang Jiayuan Machinery Co., Ltd

Tel:+86-15962351473

wechat:15962351473

skype:Joyce1989280

whatsAPP:+8615962351473

Factory Add:

No.198,Zhenbei Road,Leyu Town, Zhangjiagnag City , JiangSu Province .PRC

POST CODE :215625

|

|

Stainless Steel Beverage Filling Machine 4 In 1 Hot Filling Electric Driven Images |